What is an A-3 Report?

REFLECTION: FOR STUDENTS: “Having no problems is the biggest problem of all.”- Taiichi Ohno

FOR ACADEMICS: “Data is of course important in manufacturing, but I place the greatest emphasis on facts.”- Taiichi Ohno

FOR PROFESSIONALS/PRACTITIONERS: “Make your workplace into showcase that can be understood by everyone at a glance.”- Taiichi Ohno

Foundation

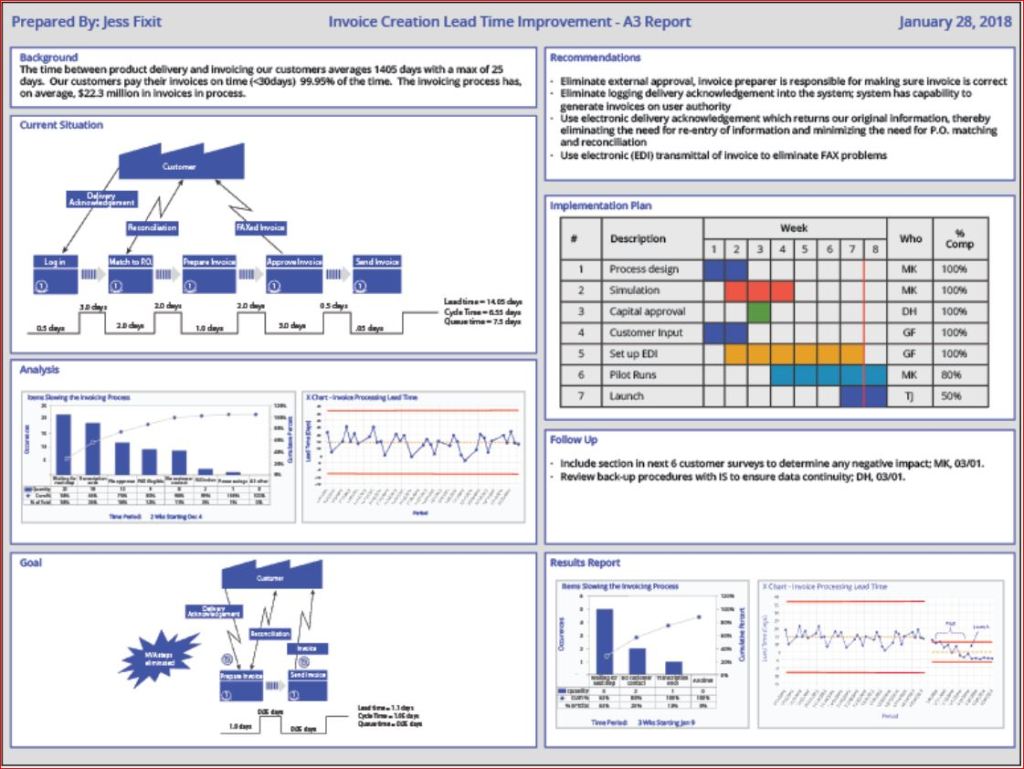

The A3 Report is a model developed and used by Toyota and currently used by many businesses around the world. The A3 Report is named for a paper size-A3 (29.7 x 42.0cm, 11.69 x 16.53 inches). The entire current state and PDCA aspects of the project are captured visually for easy communication and reference. When CIP projects use an A3 methodology to track projects, it has been demonstrated that clear visual communication helps the team members and the overall organization be more aware of the team’s progress.

A minor improvement event, in my experience, is generally four weeks to six weeks. Still, when an issue needs to be addressed thoroughly, the organization must be willing to invest more time and resources. Almost every moment of improvement time spent may be wasted if the true root cause is not adequately addressed due to failure to properly invest resources. There are four distinct phases: 1) preparation and training; 2) process mapping and current state analysis; 3) process mapping and future state analysis; and 4) implementation and ownership. I will put up a basic template below and walk through the A3 report.

Example

- Clarify the Problem

- IS/IS Not Analysis-excellent first tool to use to define the scope of the problem.

- After the scope of the problem has been defined, define the problem relative to the organization or process. The focus should always be on an underlying process or systematic issue, not an individual failure. Systematic failures are frequent but can be corrected with teamwork. The problem statement should never include a suggestion for a solution.

- Breakdown the Problem

- Clearly define the problem in terms of the 5 Why’s and 2 W’s (Who?, What?, When?, Where?, Why? And How?, How much or often?

- Set goals for improvement towards the ideal state vs current state

- Team sets S.M.A.R.T. goals relevant to block 1 state, establishing the end improvement target

- Root Cause Analysis

- Team uses focus areas from block 2 to determine Root Cause(s) employing relevant RCA tools

- Common RCA tools

- Cause-Effect/Fishbone Diagram

- 5 Why Analysis

- Fault Tree Analysis

- Pareto Chart

- Clearly state the determined root cause(s) and display the output of the tools

- Develop Countermeasures

- The team should take the root cause/causes from Block 4 and assign specific countermeasures.

- Countermeasures should directly address the root cause and, in theory, should solve the problem identified in Block 1.

- The completed fifth block is populated with any tool that will outline the countermeasures.

- Implement Countermeasures

- The team tracks the countermeasures from Block 5 and ensures each one is accomplished.

- The completed sixth block should be populated with the tool used in Block 5 to outline the countermeasures and updated as each is accomplished.

- Monitor Results and Process

- Effectiveness Check of Countermeasures

- Before/After Analysis

- SPC Control Charts

- Use Data from block 1 to determine if countermeasures from block 5 are having the desired effect relative to the target.

- If countermeasures are not effective, go back to RCA-block 4 (PDCA) and reconvene.

- Use the tool from block 6 to track countermeasure as ineffective in Block 7

- Effectiveness Check of Countermeasures

- Standardize successful processes

- If countermeasures are effective-

- Standardize all successful processes and note successful countermeasures as Standardized as they are approved using the tool from block 6 in Block 7

- A separate block can be used for Standardized processes

- If countermeasures are effective-

Conclusion

A complete A3 report can use many different tools, depending upon the problem being examined, so don’t fall into the habit of always using the exact same format. Be certain all four phases are completed. Innovation comes from creativity, so leave behind SOPs that demand exact clones of past reports. You may be dealing with a problem no person in your organization has yet to encounter, so outside of the box is thinking should always be on the table (Not locked away in a closed mind)

Bibliography

Quality Management Journal, Volume 16, 2009 – Issue 4

Published Online: 21 Nov 2017

Quality Progress Volume 49, 2009 – Issue 1

Jan 2016

The Deming Chain Reaction

REFLECTION: FOR STUDENTS: How can you weave Quality into all Management endeavors to help sustain what you are managing?

FOR ACADEMICS: How can I incorporate MORE quality concepts into class/classroom management?

FOR PROFESSIONALS/PRACTITIONERS: Do you operate in a firefighting mode, preventive mode, or risk management mode? Are those quality decisions ever made by the front line operators, or is it managers who solve the problems?

The “Whats” of Quality Culture

During my 20 years of experience as a Quality Professional I have witnessed a similar pattern emerge constantly. One book I read (Angle, 2019) captured the essence of what happens with just three observations, that I can firmly attest to as the three most impactful “Whats” that I have seen.

-The First “What” was: Sustainable Corrective Actions were not properly enacted to address noted quality failures. Pencil whipping corrective actions to meet a deadline or going after the immediate surface problem only allows the eventual recurrence of the issue.

-The second “What” was how curiously common it was for a company to not understand the power of Quality from the highest ranks, deep into the culture, and how critical not understanding the need to monitor the existence and state of the Culture of Quality was to the company. Reactive measures are firefighting tasks brought on by the need for a quick fix. A culture that chooses to ignore quality and go for the non-sustainable path will imprint those same values across the entire organization. When the organization is short term focused, so are it’s employees, so quality and profit fall over the long term.

-The third and final “What” is far more common: There may be no true strategy for Quality. No strategy for Continuous Improvement, Change Management, or Strategic Alignment that is truly Quality Driven. Too often Quality is a department that measures and inspects, and any other decision is financially driven. Pure financial drive leads to non-measurement of quality costs, impacts, and ramifications (the infamous Hidden Factory), which tends exclude Quality from risk/based business decisions not related to regulated industries. ISO claims that “over a million” companies have been certified, so if I add, let us say, 9 million other companies with various other certified QMS systems (and I am being generous) then, (using the top 15 GDP countries for the low estimate and population extrapolation for high) out of the approximately 60-100 million companies in the world the % of companies with a certified QMS is 10% to 16%. **NOTE: [Not verified numbers, just estimates to convey the current state of quality in the business world based upon available data and the numbers are always in flux.] Certification only helps push a company toward a viable QMS. Though minding your P’s and Q’s helps, a viable QMS is in no way guaranteed by a certificate.

How a Culture of Quality Impacts the World

The end result of a company allowing any one of these “Whats” to manifest beyond the level of “I’m new to this quality thing” stage of an employee’s professional development is usually to the detriment of the company’s reputation, customer retention, and the company’s ability to obtain the best ROI. Those who argue for quick and dirty quality are selling snake oil. Quick and Dirty is the Challenger disaster management mentality of “I’m in charge! NASA expects this bird in orbit! I don’t care if all the engineers in the world are telling me that it might be too big a risk!”

Human nature is to break the rules, and it takes a true Quality Culture of excellence to hold an organization to a consistent level of excellence beyond that of normal human nature. Evan a well-designed system is useless if it can be overridden by customer demand, time constraints or public pressure that might jeopardize public safety, of the safety of even one human (Bombardier Business Aircraft, 2018).

Overcoming the tendency of humans to take the path of least resistance (especially in management) is a topic for another post, but The work of quality gurus such as W. Edwards Deming, Joseph M. Juran and Armand V. Feigenbaum helped enlighten Japan beginning in the 1950’s, and Japan took off with their teachings and enriched the concept, until Japan had risen from a country decimated by war to a major economic power. In the 1970’s America began to wake up to what was happening, and the work of Deming, Juran, Feigenbaum and then Philip B. Crosby, Taiichi Ohno, and Eiji Toyoda were recognized and the path was actively pursued in the West. All looked at the philosophy a little different, but they all understood how costly it was to ignore quality (especially from competitors). Eventually the economic result of a strong quality culture (that can still be seen in Toyota) was described by Deming as a Chain Reaction (ASQ, n.d.).

Basically: improve quality →decrease costs →improve productivity → increase market share with better quality, lower price → stay in business → provide more jobs, and now Toyota is (at this time) the most profitable automaker in the world (about twice GM’s profitability).

Improve quality can relate to every kind of buzzword, but the main goals are to reduce waste, reduce variation, and provide value to the customer (for which the customer would be willing to pay). Waste, Defects, Rework, Delays, all decrease, OEE goes up, Costs drop and productivity goes up, and you then have lots of higher quality and more desirable items on the market available at a lower price. Competitors can flood the market with cheap items, but quality lasts if it is not too expensive for the market, so your market share expands due to the ability to sell a higher quality product at a more affordable price. You stay in business and your company provides more jobs as they expand market share (Victor E. Sower, 2016).

Conclusion

Culture is king. Without a proper Quality Culture, the customer will never be properly served. The Voice of the Customer guides you, but the Culture is your company’s heart. If your heart is tainted with pure desire for profit, then you are not serving the customer, but yourself. The initial investment required to improve internally can be framed as non-customer focused by some, but always remember, that inward looking improvement of the company from management to the front line worker, across every department, and every process can only benefit the customer in the end. Due to the Pareto effect, the relatively vital few companies with a viable QMS and honest Culture of Quality do clearly have a significant economic impact on our world, and all companies should ask themselves: Do they want to be one of the Vital Few or Trivial Many?

Bibliography

Angle, A. S. (2019). Unleash Quality. Milwaukee: ASQ Quality Press.

ASQ. (n.d.). The History of Quality. Retrieved from https://asq.org/quality-resources/history-of-quality

Victor E. Sower, K. W. (2016, 07). Retrieved from Quality Progress: http://asq.org/quality-progress/2016/07/basic-quality/dead-or-alive.pdf

Bombardier Business Aircraft. (2018, June 1). The Normalization of Excellence. Retrieved from https://safetystanddown.com/en/normalization-excellence