What is an A-3 Report?

REFLECTION: FOR STUDENTS: “Having no problems is the biggest problem of all.”- Taiichi Ohno

FOR ACADEMICS: “Data is of course important in manufacturing, but I place the greatest emphasis on facts.”- Taiichi Ohno

FOR PROFESSIONALS/PRACTITIONERS: “Make your workplace into showcase that can be understood by everyone at a glance.”- Taiichi Ohno

Foundation

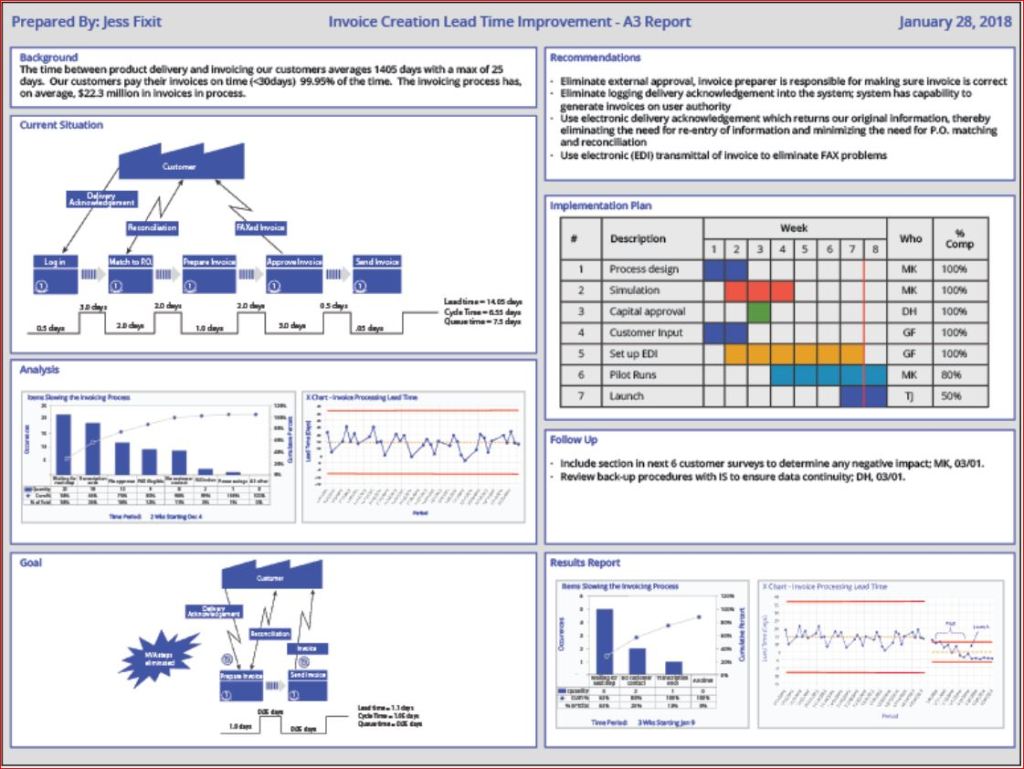

The A3 Report is a model developed and used by Toyota and currently used by many businesses around the world. The A3 Report is named for a paper size-A3 (29.7 x 42.0cm, 11.69 x 16.53 inches). The entire current state and PDCA aspects of the project are captured visually for easy communication and reference. When CIP projects use an A3 methodology to track projects, it has been demonstrated that clear visual communication helps the team members and the overall organization be more aware of the team’s progress.

A minor improvement event, in my experience, is generally four weeks to six weeks. Still, when an issue needs to be addressed thoroughly, the organization must be willing to invest more time and resources. Almost every moment of improvement time spent may be wasted if the true root cause is not adequately addressed due to failure to properly invest resources. There are four distinct phases: 1) preparation and training; 2) process mapping and current state analysis; 3) process mapping and future state analysis; and 4) implementation and ownership. I will put up a basic template below and walk through the A3 report.

Example

- Clarify the Problem

- IS/IS Not Analysis-excellent first tool to use to define the scope of the problem.

- After the scope of the problem has been defined, define the problem relative to the organization or process. The focus should always be on an underlying process or systematic issue, not an individual failure. Systematic failures are frequent but can be corrected with teamwork. The problem statement should never include a suggestion for a solution.

- Breakdown the Problem

- Clearly define the problem in terms of the 5 Why’s and 2 W’s (Who?, What?, When?, Where?, Why? And How?, How much or often?

- Set goals for improvement towards the ideal state vs current state

- Team sets S.M.A.R.T. goals relevant to block 1 state, establishing the end improvement target

- Root Cause Analysis

- Team uses focus areas from block 2 to determine Root Cause(s) employing relevant RCA tools

- Common RCA tools

- Cause-Effect/Fishbone Diagram

- 5 Why Analysis

- Fault Tree Analysis

- Pareto Chart

- Clearly state the determined root cause(s) and display the output of the tools

- Develop Countermeasures

- The team should take the root cause/causes from Block 4 and assign specific countermeasures.

- Countermeasures should directly address the root cause and, in theory, should solve the problem identified in Block 1.

- The completed fifth block is populated with any tool that will outline the countermeasures.

- Implement Countermeasures

- The team tracks the countermeasures from Block 5 and ensures each one is accomplished.

- The completed sixth block should be populated with the tool used in Block 5 to outline the countermeasures and updated as each is accomplished.

- Monitor Results and Process

- Effectiveness Check of Countermeasures

- Before/After Analysis

- SPC Control Charts

- Use Data from block 1 to determine if countermeasures from block 5 are having the desired effect relative to the target.

- If countermeasures are not effective, go back to RCA-block 4 (PDCA) and reconvene.

- Use the tool from block 6 to track countermeasure as ineffective in Block 7

- Effectiveness Check of Countermeasures

- Standardize successful processes

- If countermeasures are effective-

- Standardize all successful processes and note successful countermeasures as Standardized as they are approved using the tool from block 6 in Block 7

- A separate block can be used for Standardized processes

- If countermeasures are effective-

Conclusion

A complete A3 report can use many different tools, depending upon the problem being examined, so don’t fall into the habit of always using the exact same format. Be certain all four phases are completed. Innovation comes from creativity, so leave behind SOPs that demand exact clones of past reports. You may be dealing with a problem no person in your organization has yet to encounter, so outside of the box is thinking should always be on the table (Not locked away in a closed mind)

Bibliography

Quality Management Journal, Volume 16, 2009 – Issue 4

Published Online: 21 Nov 2017

Quality Progress Volume 49, 2009 – Issue 1

Jan 2016

Team Development

REFLECTION: FOR STUDENTS: When institutions mandate team learning, were you provided proper project management skills or were you thrown to the wolves to meet administrative requirements? Teamwork should be a holistic process, and if team learning is mandated, then the proper training should be provided for all teams to begin learning on an equal footing (a few freshmen out of high school may be in the same class as project managers). You are a customer! Do not fear the administration and use your Voice as a Customer to demand proper teaching methods be provided.

FOR ACADEMICS: I have heard horror stories of the teams that never move beyond forming during mandated team projects, and then the entire team is penalized no matter how hard they worked or how much they learned. In real life, an obstinate member of a team would be kicked out by the sponsor or team leader (or even fired from their job) before that member was allowed to impede the goal of the team (after some serious coaching). Still, academia frequently masks that aspect of the private sector from students. Have you integrated yourself as the “sponsor” to allow the team leader or team to appeal directly to you to resolve unresolvable conflict issues, perhaps making it part of the grade (based upon the team’s presentation and documentation of any issues)?

FOR PROFESSIONALS/PRACTITIONERS: Do you consider likely team dynamics and personal histories that might be significant distractions or believe the project will blind the team members to personal biases? If you believe the goal will overcome personal biases, I would say it can, but usually only under duress. Adding extra factors for a team to overcome is like adding additional factors to a DOE. It takes many more runs before they are sure they have it right, so if you know of conflict factors that can be eliminated, the time to do it would be when the team is chosen, though sometimes there are not enough resources for that level of filtering.

Common Types of Teams

Teams can manifest as required to achieve the goal, and it is essential to remember that the configuration of the team will be a significant contributor to how the team functions, so be sure your team is configured with the end goal in mind.

- Process Improvement Teams

- Self-Managed Teams

- Temporary/ad hoc teams

- Work groups

- Cellular teams

- Special Project Teams

- Virtual Teams

- Combinations of two or more of the above types

Team Selection

Management should select the team leader to ensure 100% management support for the team’s goal.

Team members may be selected by management or the leader. Still, I would suggest empowering a leader to choose the best team when a team leader chooses his/her team, using the five primary areas of competence known as the KESAA factors to analyze the fit of the candidates for the needs of the project.

Formal Education, Degrees, Educational Certifications, Professional Certifications, Self-Study achievements

Experience

Time spent actively applying knowledge and skills in pertinent types of organizations and industries and in jobs/positions held

Skills

Skill certifications documented training and demonstrated proficiency in the use of relevant tools and equipment

Aptitude

Natural talent, capability, capacity, innate qualities, deftness, adaptability to change, high learning speed

Attitude

Manner of showing one’s feelings or thoughts; one’s disposition, opinion, mood, ideas, beliefs, demeanor, state of feeling, reaction, bias, inclination, emotion, temperament, mental state, frame of mind, ease in accepting and adopting new or changed plans and practices.

-After utilizing a KESAA analysis, be sure you have every need for the project covered with a well-chosen cross-functional team.

Stages of Team Development

Stage 1: Forming

- Proud to be selected

- Anxious

- New team experience

- Forming team structure

Individuals come together and merge, each with their perceptions and priorities. This forming helps the team to move closer to a single entity and to define and clarify the team’s purpose, goals, and roles and rules for acceptable behavior within the group (norms).

Stage 2: Storming

- Individualistic thinking

- Struggle between external loyalties and devotion to team goals

- Fluctuating attitudes

- Confrontations

- The team’s task is understood

At this point is when individual goals conflict with team needs and objectives, and initial decisions are based upon old paradigms or perhaps just old emotions and conflicts.

Current information relative to the task and goal must be pooled and utilized. Then the team has to begin to shape itself by overcoming major conflicts and focusing on the proper behavior required to succeed for the next step in the team’s evolution.

Stage 3: Norming

- Team coalesces

- Cooperation

- Individuals willing to dialogue

- Conflicts reduced

- Focus is on team objective

At this stage, the individual members of the team overcome their personal biases and previous conflicts, coalescing into a team. The team finds itself shifting the full focus of the team’s efforts to meeting team-related challenges rather than individual concerns. Discussion of differences for the sake of the team becomes the Norm, resulting in a standard of team cooperation and constructive dialogue.

True Diversity of Thought emerges. Note: from my experience- (if the Norm fails to be achieved, the Performing level usually will not be optimal, though it can still succeed).

Stage 4: Performing

- Team has matured

- Smooth, cohesive unit

- Focus on process and goal

- Feelings of satisfaction

- Achieving goals

The team members have a good understanding of one another’s strengths and weaknesses, and how they contribute to the end goal and are effectively able to resolve conflict and appreciate the team as an individual entity. This is the stage where the real strides toward achievement are occurring.

Adjourning

Tuckman’s original model ended at the performing stage, but a final stage is now standard- the Adjourning stage. The reason this phase is so critical is that though the stages represent the normal logical procession of team development, team dynamics can influence the actual flow of progress. Forcing teams to regress to earlier stages to overcome previous assumptions about one another, decisions made upon inaccurate information, or to welcome new team members is a real possibility. Some teams never progress beyond a certain point of development due to outside forces combined with inner team dynamics.

Limited project duration and poor group dynamics can be significant issues.

Anytime a team successfully achieves a Performing level, and the team’s mission has been successful, the post-project stage of Adjourning should be performed to capture lessons learned, what was accomplished, complete, and assign documentation, celebrate, and formally disband.

(Russell T. Westcott, 2014)(CSSBB Primer, 2014)(Kubiak, 2017)

Conclusion

Team Dynamics are often overlooked during critical projects for the data, but important decisions are often made based upon how the individual members of the team work together as a team. Never underestimate the importance of a leader and facilitator with excellent soft management skills.

Bibliography

CSSBB Primer. (2014). West Terre Haute , Indiana: Quality Council of Indiana.

Kubiak, T. a. (2017). The Certified Six Sigma Black Belt Handbook Third Edition. Milwaukee: ASQ Quality Press.

Russell T. Westcott. (2014). The Certified Manager of Quality/Organizational Excellence. Milwaukee, WI: ASQ Quality Press.

8D vs PDCA & DMAIC

REFLECTION: FOR STUDENTS: Are you using critical thinking or using a paint by the numbers method to solve problems?

FOR ACADEMICS: Are you providing your students with the tools needed to distinguish between “guidelines” and mandates?

FOR PROFESSIONALS/PRACTITIONERS: Is your organization allowing you find the true root cause of an issue or forcing you to fill out a form within a certain time frame? Try to convince top management to allow teams to properly explore root causes, and if management continues to violate standards by ignoring the concept of due diligence in favor of meeting the closure rate when more time should have been allotted- file a CAPA. It is your duty as a Quality Professional.

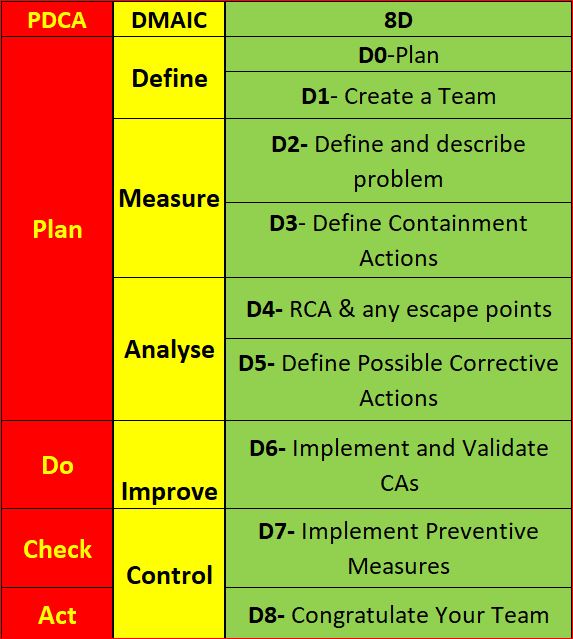

What is 8D?

I have been performing CAPAs for many years. I have employed many methods: The Tried and True PDCA, the DMAIC approach, and even utilized the A3 path when the visual display of ongoing CAPAs was critical to communication (or mandated by policy). The Eight Discipline (8D) Approach has been the path that was least used by me, as it was (to me) least flexible. For those who are proponents, it works fine, but it seems more about CAPA closure by the numbers and documentation than it is about teaching your team to be independent critical problem solvers. While 8D will work well in any industry if implemented correctly, 8D is more template-based than PDCA. Have no doubt, DMAIC is quickly becoming template-like via software applications. A basic template is a useful guide, but the less controlled the problem solving, the more likely the team is to arrive at an innovative solution.

For those who are unsure what the Eight Disciplines are, let me elaborate on the Eight Disciplines:

Originally Ford developed the 8D method in the late 80s, and it spread to most of the automotive industry.

The Ds in this method are not acronyms (as many seem to struggle with), but rather a set of “Disciplines” to follow for problem-solving. These Disciplines were widely transferred to “forms” that became “8D Forms”, used for root cause analysis and correction of problems with unknown causes.

8D Method

- D0- Plan for solving the problem and determine resources needed

- Before 8D analysis begins, proper planning will always translate to a better start.

- SME Input

- Collect data on issues

- Identify any need for an Emergency Response Action (ERA)

- D1-Use a Team

- Choose the right type of team, right team members

- Teams require proper preparation.

- Set the ground rules

- 8D must always have two key members: a Leader and a Champion / Sponsor

- D2- Define and Describe the problem

- Specify by identifying in quantifiable terms the who, what, where, when, why, how, and how many (5W2H)

- 5 Why or Repeated Why (Inductive tool)

- Problem Statement

- Affinity Diagram (Deductive tool)

- Fishbone/Ishikawa Diagram (Deductive tool)

- Is / Is Not (Inductive tool)

- Problem Description

- D3- Develop interim containment plan

- Implement Interim Containment Actions (ICA)

- Verification of effectiveness of the ICA is always recommended to prevent any escapes to customers

- D4- Determine, identify, and verify root causes and escape points

- Comparative Analysis listing differences and changes between “Is” and “Is Not”

- Development of Root Cause Theories based on remaining items

- 5 Whys

- C&E Diagrams

- Determine Escape Point, which is the closest point in the process where the root cause could have been found but was not

- Review Process Flow Diagram for location of the root cause

- D5- Choose Permanent Corrective Action (PCA)

- Establish the Acceptance Criteria which include Mandatory Requirements and Wants

- Perform a Risk Assessment / Failure Mode and Effects Analysis (FMEA) on the PCA choices

- Based on risk assessment, make a balanced choice for PCA

- Select control-point improvement for the Escape Point

- Verify the PCA will resolve root cause of problem and any escape points issues

- D6- Implement and Validate PCAs for problem/nonconformity

- Define and Implement the best PCAs

- Validate PCAs using objective measurement

- D7- Prevent recurrence

- Review Similar Products and Processes for problem prevention

- Develop / Update Procedures and Work Instructions for Systems Prevention

- Capture Standard Work / Practice and reuse

- Assure FMEA updates have been completed

- Assure Control Plans have been updated

- Preserve and share the knowledge, preventing problems on similar products, processes, locations or families

- D8- Congratulate your team

- Archive the 8D Documents for future reference

- Document Lessons Learned on how to make problem-solving better

- Before and After Comparison of issue

- Celebrate Successful Completion

If you have interacted with a Six Sigma Team or a PDCA Root cause team, you know how the DMAIC and PDCA compares. For illustration, I have them side by side. 8D is much more broken down than the others. Using PDCA, the assumption is that a team acting in a PDCA cycle will have top management support and that those involved have the proper knowledge and training required to gather and analyze data to determine a solution. Also assumed is that the resources are available to improve the issue, Measurement of the results is always part of the cycle, and reacting to the final results of the Check on the improvement will yield either a successful CA/Improvement or begin a repeat of the cycle (basically the scientific method).

Most consider DMAIC the same as PDCA, just more focused on clarifying the PDCA cycle in order to reduce iterations by shifting the focus away from potential multiple cycles to achieving the most effective improvement the first time (though failure is still built into the process). The 8D method is once again pretty much the same process, as you can see.

When DMAIC and 8D are highly templated, a lot of the focus moves from solving the root cause toward closing the CAPA within the mandated time.

Making problem-solving quick and easy makes it easy to pencil whip. I would suggest you avoid the potential pencil whip methods. Have a group that must think for themselves and writes the report using only basic guidelines (not templates).

Conclusion

While I have clearly indicated I am not a fan of 8D and not happy with the way DMAIC is being pushed into templates, I do not mean to say that any single technique is better than another. Essentially, they are all the same method, re-focused. 8D is very conducive to utilizing documentation of project results and assigning work breakdown structure accountabilities (WBS) DMAIC is better for cross-functional communication and can be used for similar documentation. The Shewhart PDCA cycle is more of a high-level outline that allows the improvement project to be adjusted as required by SMEs. Choose the method that suits your needs, and as long as a cross-functional team performs proper due diligence with full top management support, the outcome will usually be similar regardless of the method chosen.

Bibliography

ASQ. (nd). ASQ Quality Resources. Retrieved from WHAT ARE THE EIGHT DISCIPLINES (8D): WHAT ARE THE EIGHT DISCIPLINES (8D)?

Pruitt, W. F. (2019, May). A Disciplined Approach. Retrieved from ASQ Quality Progress: http://asq.org/quality-progress/2019/05/back-to-basics/a-disciplined-approach.html

Quality One. (nd). Quality One. Retrieved from Eight Disciplines of Problem Solving (8D): https://quality-one.com/8d/